Production structure

At Vega Composites, our engineers use specialized 3D design software such as Solid Edge® to collaborate with customers on the development of new projects. We work closely with clients to design and verify components for optimal performance. If a project is provided directly by the customer, our Technical Office is dedicated to finding the most appropriate technical and aesthetic solutions for specific applications. We work alongside our customers and quality management system to generate production documentation and internal controls. Our commitment to technical excellence and customer satisfaction ensures that Vega Composites is a trusted partner for composite solutions.

Composites Department

At our state-of-the-art composite department, we leverage the latest technology and machinery to design and construct composite components and facilities. Our controlled temperature and humidity “clean room” ensures direct management of critical quality parameters for the finished product. The rolling team, in collaboration with our technical department, is proficient in the primary composite processing technologies, including the processing of pre-impregnated materials, vacuum application, autoclave cooking, mold production, and resin infusion for large components.

At every stage of production, we monitor every detail to track and certify the quality of the finished product. Our commitment to quality and innovation ensures that Vega Composites is a trusted partner for businesses seeking superior composite solutions.

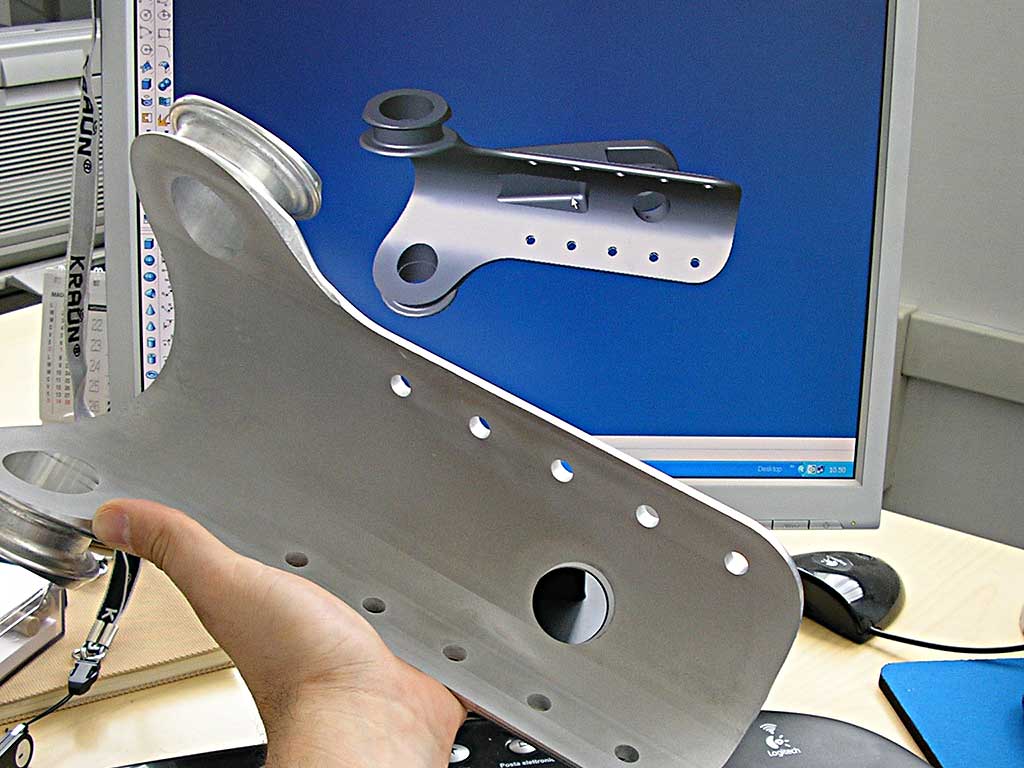

Mechanical Workshop

At Vega Composites, our machine shop benefits from highly skilled technicians, 3, 4, and 5-axis CNC machines, and specialized CAD-CAM programs such as hyperCAD-Hypermill for the processing of plastic and metal materials. Unlike other companies in the sector, we have an in-house machine shop that enables the creation of highly integrated, specialized, and technologically advanced products.

Our technical office and workshop collaborate seamlessly to achieve the highest levels of quality and flexibility in order management. With the ability to internally create models, molds, and equipment, we have total control over the production process, ensuring that our clients receive the best possible solutions for their unique needs. At Vega Composites, we are committed to excellence in every aspect of our work, and our machine shop is no exception.

Research & Development

At Vega Composites, our products are designed for an elite market and feature high technological content, with meticulous attention to the smallest details. We are committed to continuously investing in R&D to remain competitive and push the boundaries of what is possible in our industry.

Our dedication to research and innovation has earned us a reputation as a leading provider of composite solutions for clients across a range of sectors. We pride ourselves on delivering exceptional products that meet the most demanding requirements, from design and development to manufacturing and testing.

Whether you are looking for a custom solution or a standard product, Vega Composites has the expertise and experience to deliver the best possible results. Contact us today to learn more about how we can help you achieve your goals and stay ahead of the competition.