Business Sectors

Vega Composites is a leading supplier of high-performance composite materials for Aerospace, Aviation, and Space projects. With our UNI EN 9100 certification, we are committed to providing exceptional quality and excellence in every product we offer.

Our team of experts specializes in developing customized solutions for multi-band radomes, carbon fiber reflectors, UAV, ground station systems, satellite shields, and components. We take pride in utilizing non-conventional materials such as dyneema, quartz, and kevlar prepreg with cyanate ester resin to help our clients achieve their goals and exceed expectations.

At Vega Composites, we prioritize the highest standards of quality, reliability, and customer service. Trust us to deliver premium composite materials and exceptional support for all your Aerospace, Aviation, and Space needs.

Defence

Vega Composites offers Mechanical and RF design testing and simulation capabilities to develop integrated systems based on customers’ specifications or projects. Whether built-to-spec or built-to-print, our expertise allows us to deliver the highest quality products for Land, Airborne, and Naval applications.

As a strategic long-term supplier, we work closely with key industry players and institutional bodies to provide top-of-the-line composite materials for all your needs. We pride ourselves on our ability to work in synergy with the components provided by Gruppo Pasquali, enabling us to offer the most comprehensive solutions available.

At Vega Composites, we are committed to excellence in every aspect of our business, from product design to customer service.

Super Yacht & Marine

At Vega Composites, we have a long-standing passion for the nautical industry, which has propelled us to become a key supplier for the most important Super Yacht companies and America’s Cup Teams. Our expertise in composite and metal-composite hybrid structures has been instrumental in introducing groundbreaking innovations that improve vessel performance and efficiency.

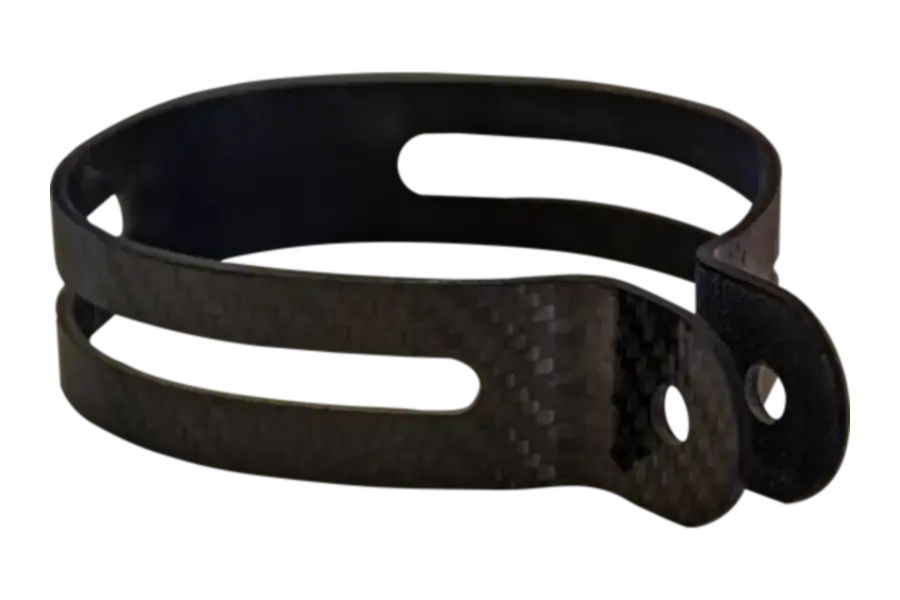

Our team has led the way in ship core part redesign, replacing traditional metal components with lighter and more durable composite materials. Our composite solutions include carbon spreaders, pole tenders, foils, swivels, and furlers, as well as booms, among others.

As a trusted supplier, we work closely with our clients to provide customized solutions that meet their unique needs and exceed their expectations.

Automotive

Our company specializes in various high-end aftermarket parts engineering and production in response to customers’ requests. With expertise in prepreg autoclave curing, 5-axis CNC machining, and exceptional attention to detail, we have become a valued partner to some of the most important motorbike and automotive brands in the industry.

We offer a range of products, including exhaust systems, frames, and various decorative and miscellaneous parts. Our commitment to delivering the highest quality products and exceptional customer service is unmatched in the industry.

Whether you require a one-off prototype or high-volume production, we can provide customized solutions that meet your specific needs and help you achieve your desired outcomes.

Telecommunications & Civil applications

In the last decade, Vega Composites has taken on technological challenges in a variety of civil applications, including airports, railways, marine, and more. Our company offers Built-to-Spec (BtS) and Built-to-Print (BtP) solutions for a range of products, including radomes and complete antennas, Foreign Object Debris (FOD) systems on airport runways, unmanned submarine exploring units, tailor-made parts for oil and gas inspection rods, robot parts for automated systems in industrial applications, and much more.

We take pride in our ability to provide customized composite solutions that meet the specific needs of our clients in these diverse industries. Our team of experts is dedicated to working closely with our clients to ensure that our solutions exceed their expectations, and we are committed to delivering premium quality composite materials and exceptional service in all of our projects. Contact us today to learn more about how we can assist you in your civil applications.

Design

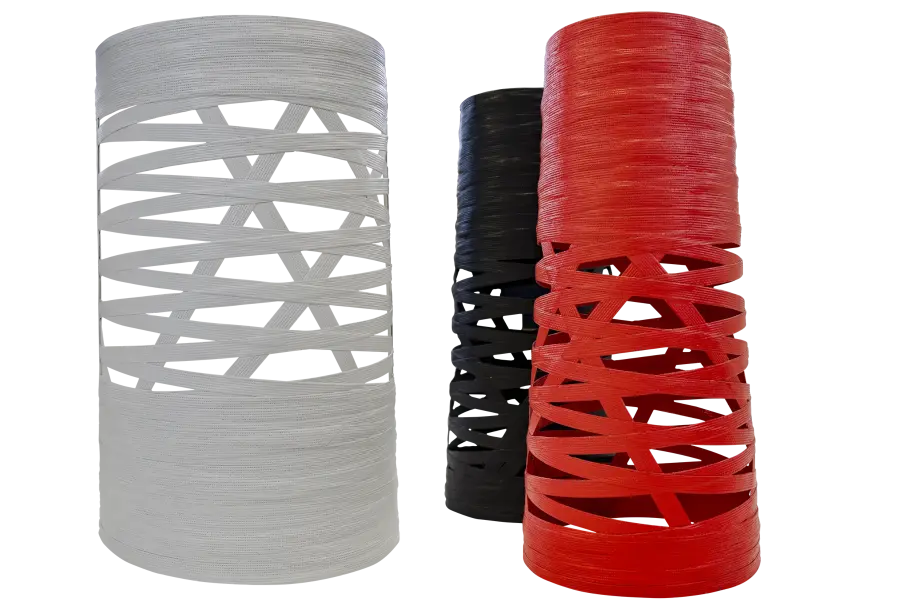

Our team at Vega Composites is dedicated to creating composite solutions that not only provide functional benefits but also evoke emotions through innovative designs. We believe that different combinations of materials, resins, and colors can be leveraged to achieve unprecedented Emotional Design.

We have had the privilege of collaborating with top-level brands in the interior design and architectural industries, and our portfolio includes lighting structures at Malpensa Airport, illumination systems for the “Madonnina” statue atop Milan Cathedral, and unique masterpieces commissioned by leading contemporary artists.

At Vega Composites, we take pride in our ability to bring our clients’ visions to life through customized composite solutions that are both functional and visually stunning.

Industrial Automation

Discover how composites have become vital in various industries due to their exceptional mechanical properties combined with lightweight components. In the automation and robotics sector, these materials play a crucial role in enhancing productivity by reducing mass and inertia in moving parts. With 20 years of experience, VEGA COMPOSITES specializes in designing and manufacturing fully customized systems that meet the requirements for strength, rigidity, and lightweight construction of mechanical components. Our products ensure maximum reliability, repeatability, and durability.

We have developed specific epoxy-based systems that are approved for medical and food environments, complying with regulations such as 10993-3 and 10993-5 regarding low cytotoxicity and minimal molecular release during use. Our composite systems seamlessly integrate with mechanical parts (made of lightweight alloys, steel, or titanium), often incorporated within the structure itself (co-lamination). These components are precision machined using CNC machines or assembled on dedicated precision benches using high-performance two-component epoxy adhesives.